Electric Drink Cooler - Part 3

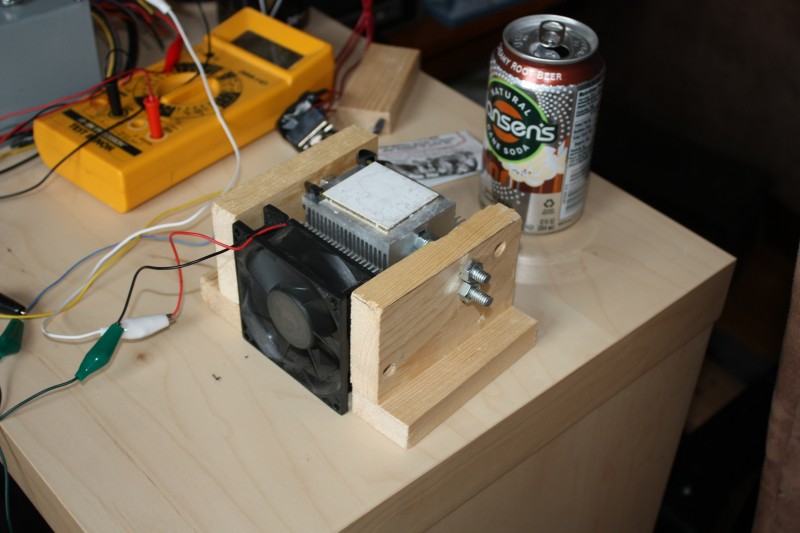

Once I confirmed that the setup will cool a drink, I finished mounting the heat sink.

During the initial test, I noticed that the steel plate I used as the drink platform caused a lot of inefficiency. I had a roll of aluminum flashing, so I cut a piece to fit the frame. Aluminum is much better at conducting thermal energy than steel.

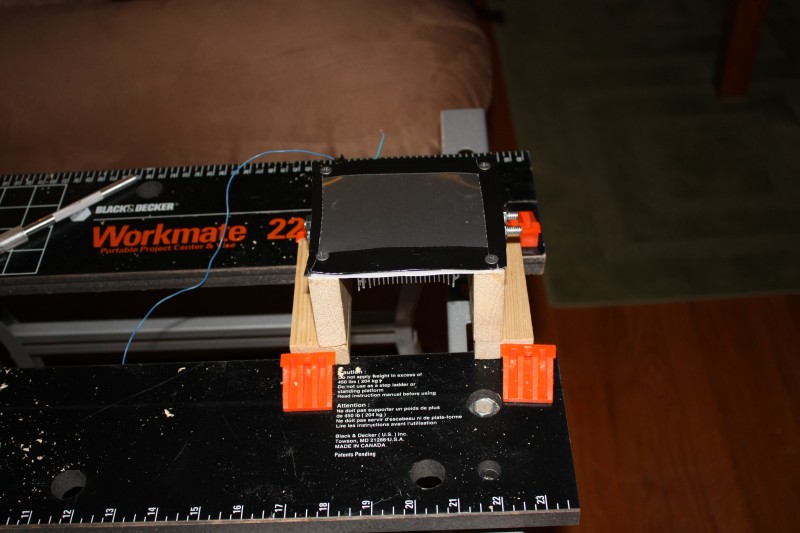

I tested the rig with the aluminum mount.

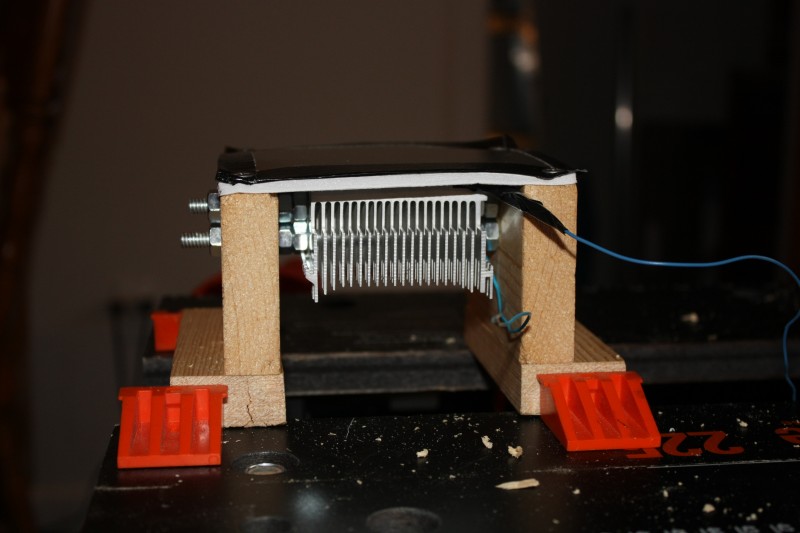

To make the aluminum completely flush with the top of the TEC I cut a piece of foam board. A 24"x36" piece of foam board costs me $1 at a dollar store. This had the added bonus of holding the TEC in place.

I bought the foam board because I thought I would find a use for it. After working with it, I can safely say that it will be a staple of my on-hand materials. It is relatively strong, lightweight, and easy to shape with an X-Acto knife.

I put duct tape around the edges of the aluminum to cover the sharp edges. I drilled the aluminum and screwed it into the frame.

I noticed a problem with this mounting. When I screwed the aluminum down, the center of the plate bulged, losing physical contact with the TEC. I tried to loosen the screws slightly as well as adding thermal paste. This seemed to help, but it is still not optimal, although it still performs better than when I used a steel plate.

Although I could have called the physical construction of this project done at this point, I can't leave things alone.